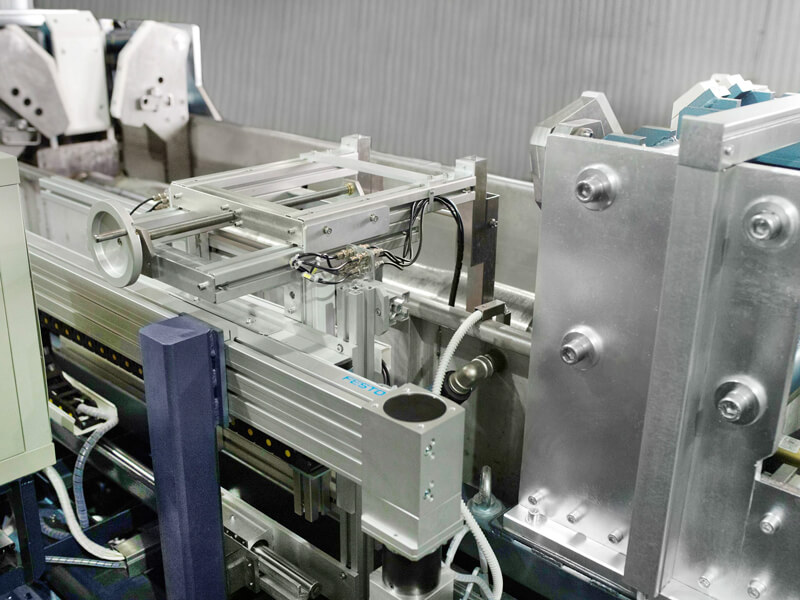

The axle is inspected in radial and axial directions while it is rotated in the immersion tank and the UT scanner moves along it. The System scans axles along their entire length, except the dead zones in the axle center and bolt holes. The AUTS Axle-4 OS-4 estimates the equivalent size and depth of the defect.

Key Features:

- ergonomic design;

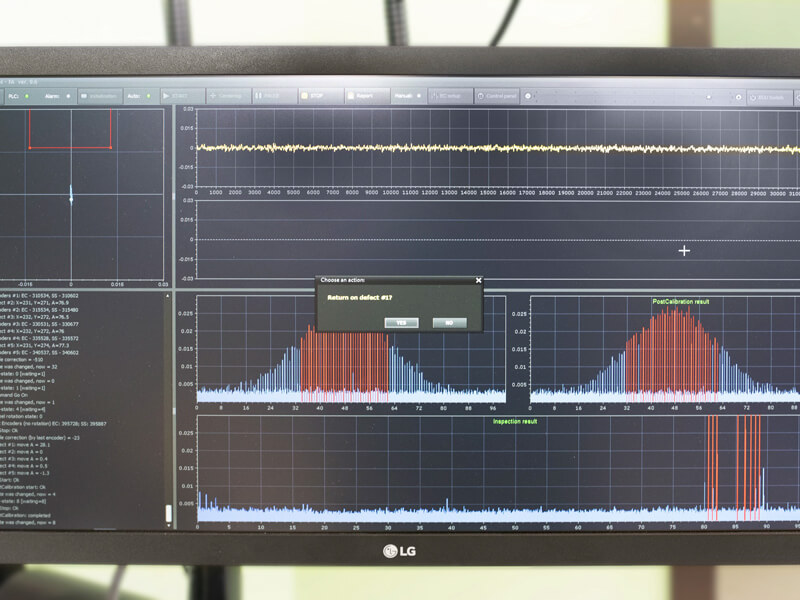

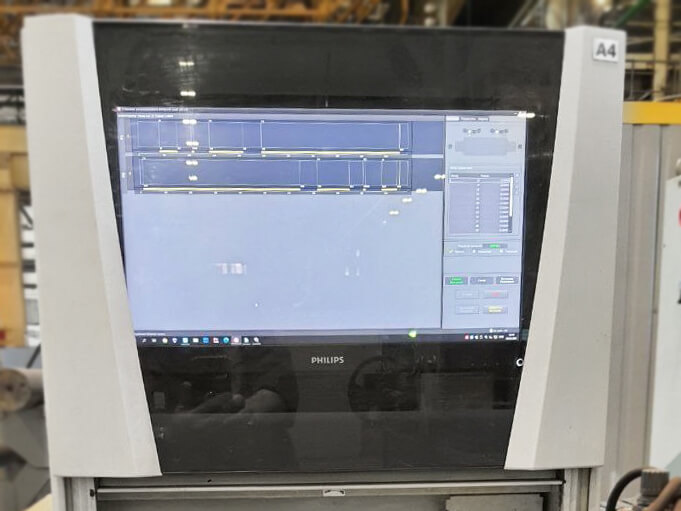

- user-friendly interface;

- code compliance: ISO 5948; EN 13261; М101; BN 918275;

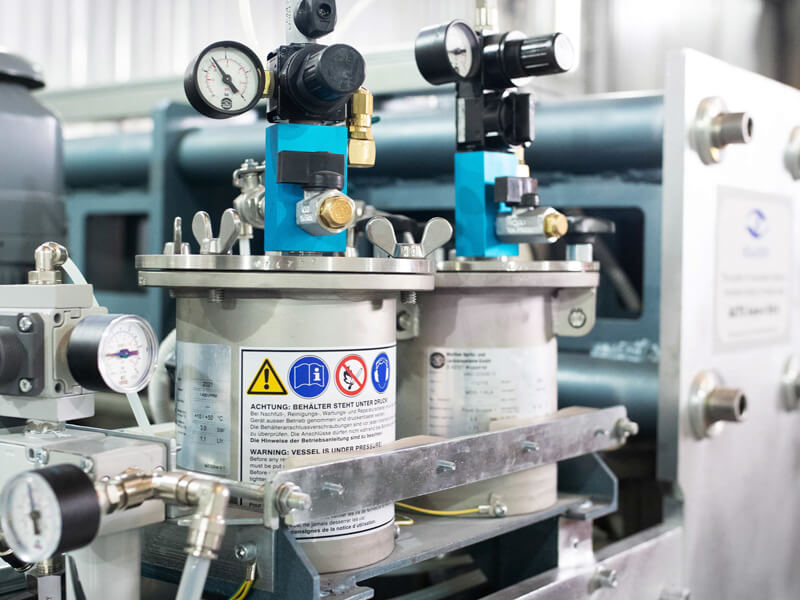

- closed-circuit system of immersion liquid intake, supply, and purification;

- scanner position visualized on the screen of the control panel;

- automatic finding of the starting;

- pre-stored settings for each axle type, minimizing the setup time during the change of the roll;

- online viewing of B-scan or the set of peaks;

- 2D projections with an option to select and view the defective cross-section;

- saving test results to the system database;

- automated accept / reject decisions in compliance with the regulatory requirements;

- customized forms of report.

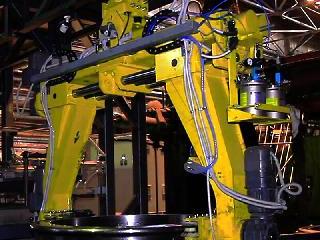

Photo

Feedback