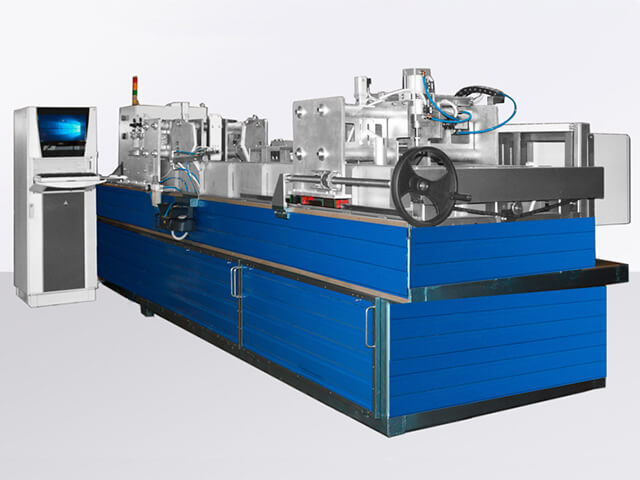

Eddy current testing System of rails EDC RAIL 5065 allows to perform an automated eddy current testing for presence of the surface defects. Main defect types that are subject to testing by the System are the surface defects such as cracks, laps, hairline cracks located on the outer surface of the rail head and rail shoe of 49Е1, 60Е1, UIC60 rail types etc in accordance with EN 13674–1–2017 requirements.

Metallurgy and machinery

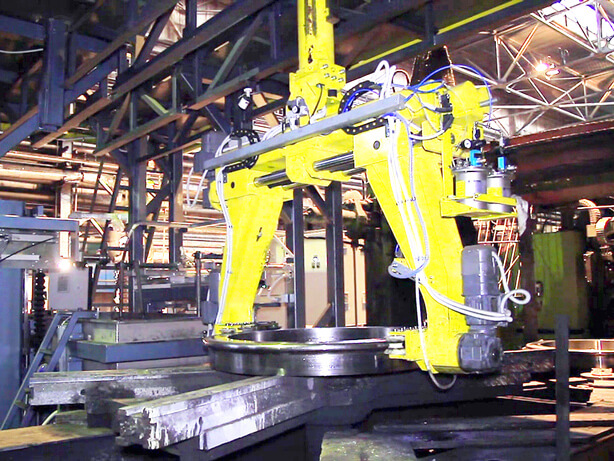

Since early 2010, the OKOndt Group company has been conducting scientific-and-research and experimental-and-design works in the field of automation of the non-destructive testing methods for the railway wheelset elements testing. Implementation of the developed Systems for automated ultrasonic testing AUTS Axle-4 OS-4 and mechanized magnetic particle testing OS-38 (hereinafter – the Systems) enabled the enterprises of PJSC «INTERPIPE NTRP» and PJSC Lugcentrokuz a. S. Monyatovsky to promote their product at the world market and successfully certify their quality labs for compliance with requirements of European and American regulatory documents.

Ultrasonic method occupies a special place in non-destructive testing. Being one of the first and the most widespread it allows to detect both surface and inner defects of various types, perform thickness gauging and non-destructive structuroscopy.

Nowadays, the railway transport is one of the major means for transportation of goods and passengers. To assure the safety of cargo traffic it is crucial to use high-quality elements of the railway car wheelsets which are highly succumbed to a dynamic loading in-service. That is why the quality control during production of one of the wheelset elements, namely axles, is critical.

Work rolls is the main tool of the rolling manufacture, which ensures due quality of the finished rolled products. Uninterrupted operation of the powerful rolling mill and high-quality finished products depend a lot on the mill rolls surface condition and their quality.