ETS2-77 purpose

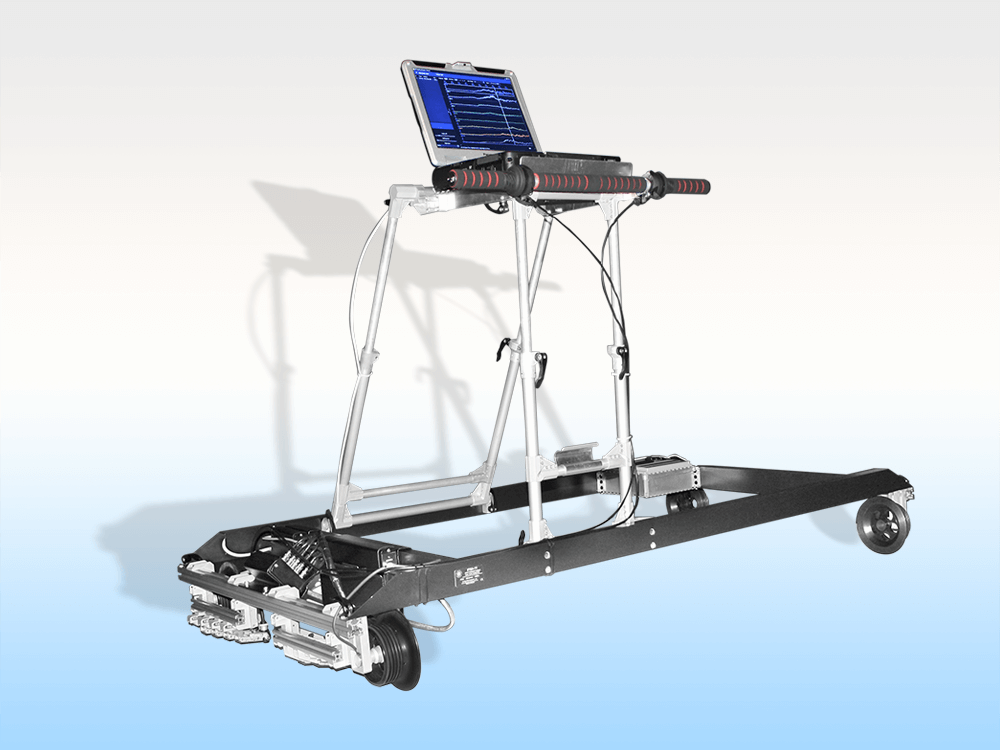

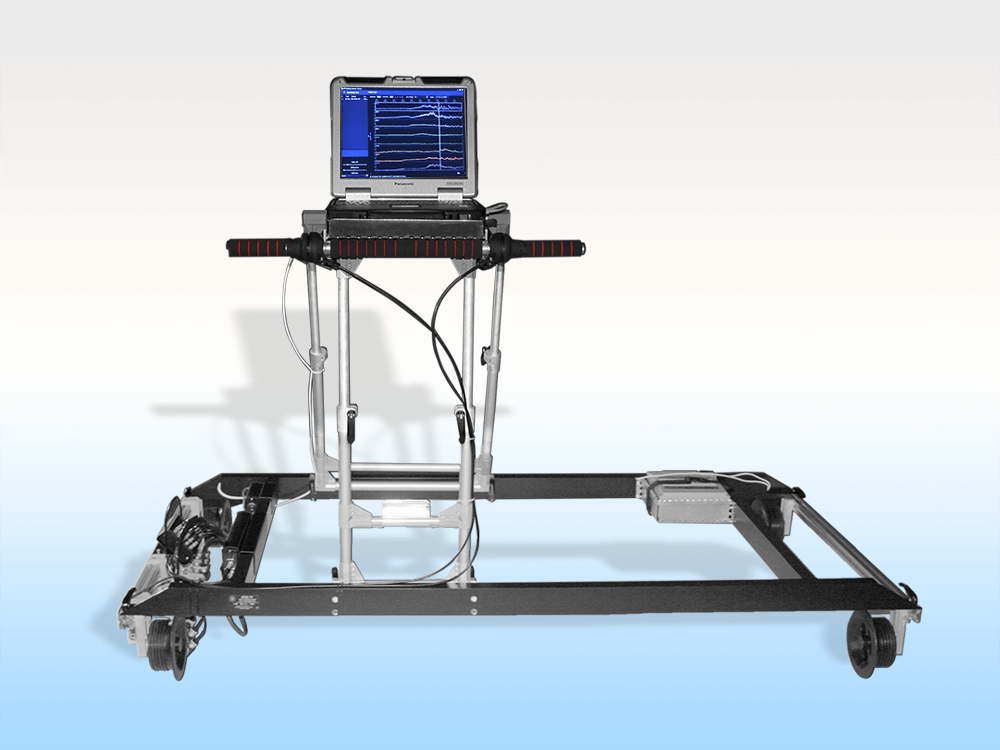

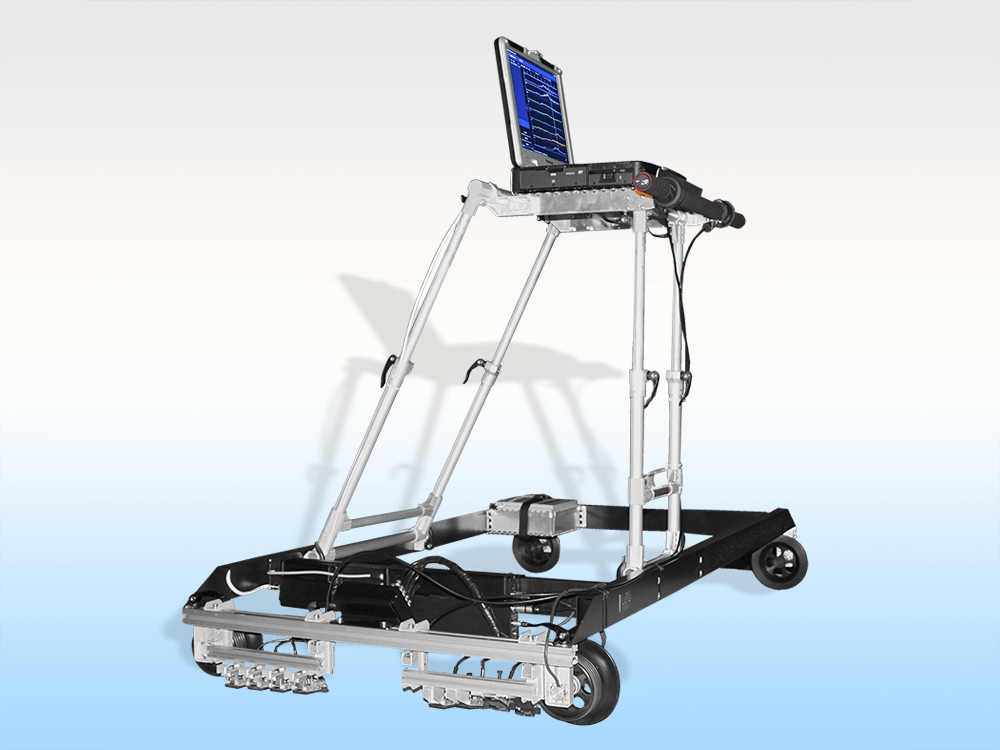

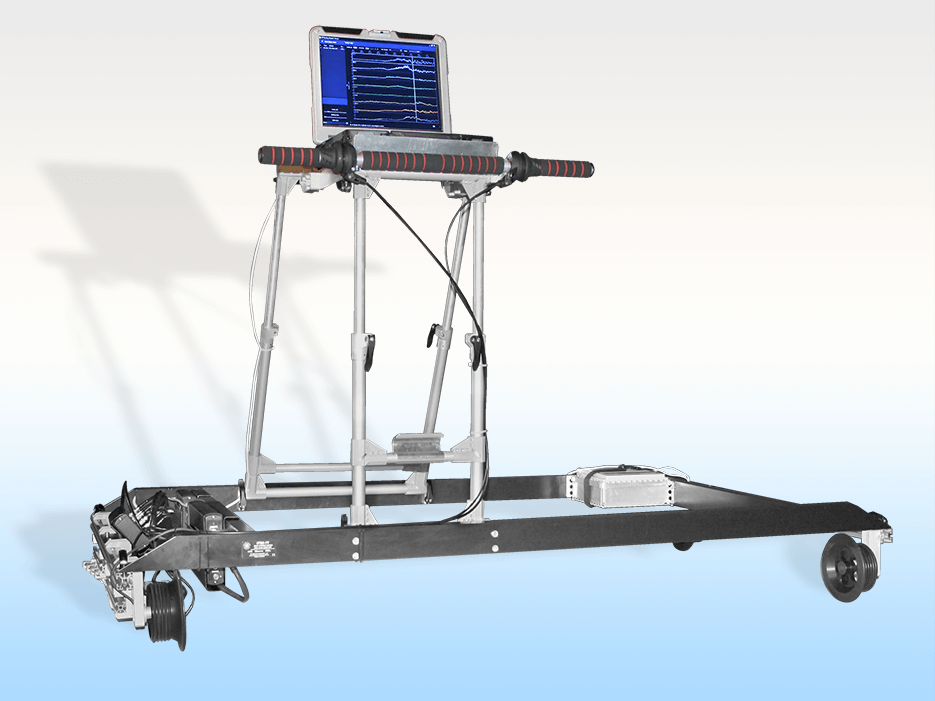

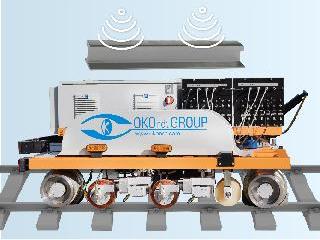

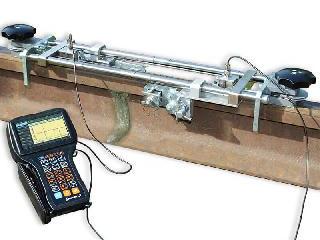

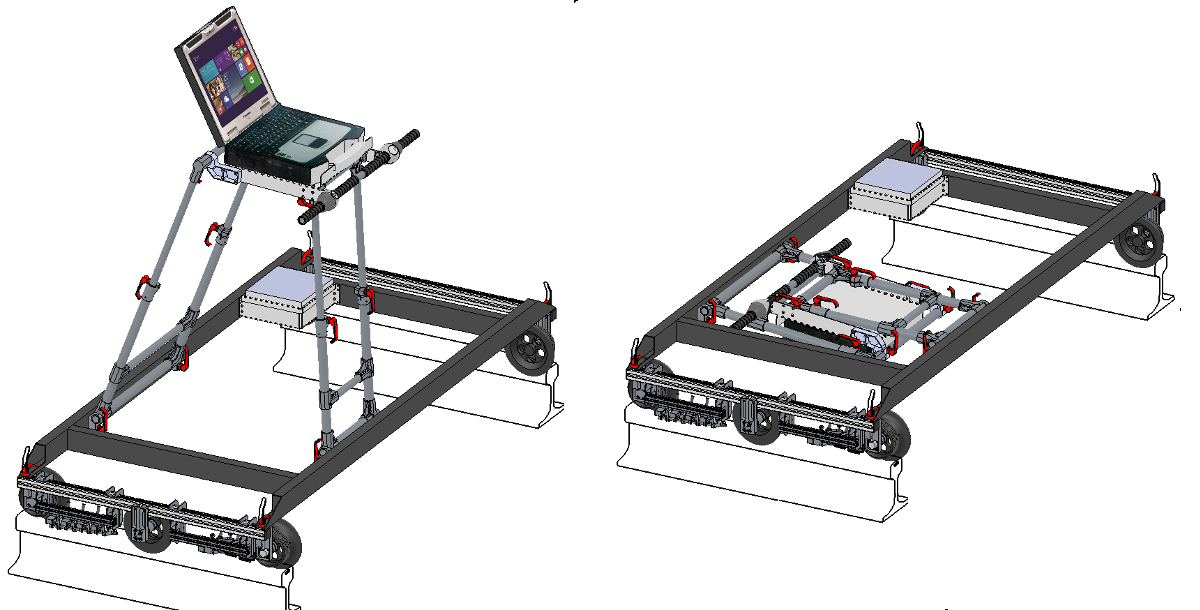

The ETS2-77 is intended for the mechanized inspection of rails and switches as well as confirmation of the results of a grinding application. The device is capable of testing a wide range of rail profiles.

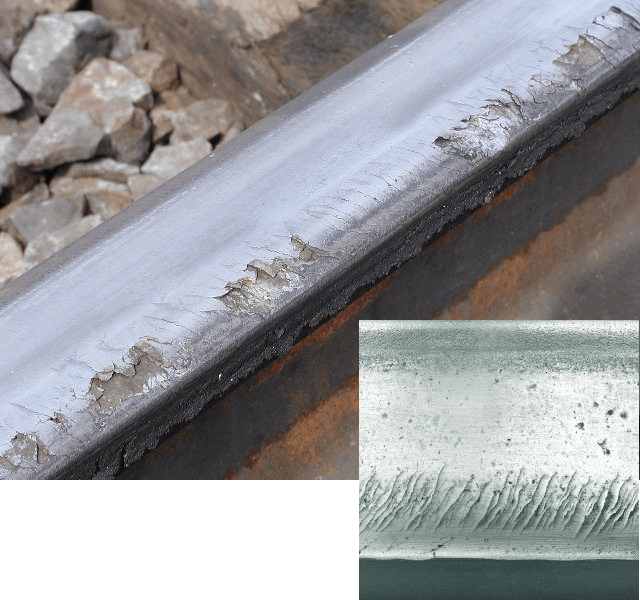

The eddy current technology enables localizing the following surface defects:

- progressive transverse cracking (International Defect Code (UIC) 211);

- fissuring /scaling at the gauge corner (International Defect Code (UIC) 2223);

- shelling of the gauge corner (International Defect Code (UIC) 2222);

- field flow or field cracking (International Defect Code (UIC) 225).

The eddy current rail inspection equipment ETS2-77 evaluates the vertical depth of the defect, thus allowing a more efficient management of rail defects. The inspector can easily decide on the appropriate defect removal method: grinding, milling or re-railing, which saves time and money.

APPLICATION

- possibility to control the rail track and the track switch;

- selective control of the separate rail track areas;

- post grinding machines control;

- all main rail profiles controlР50, Р60, 49E1, UIC 60 and others.

ETS2-77 flaw detector advantages

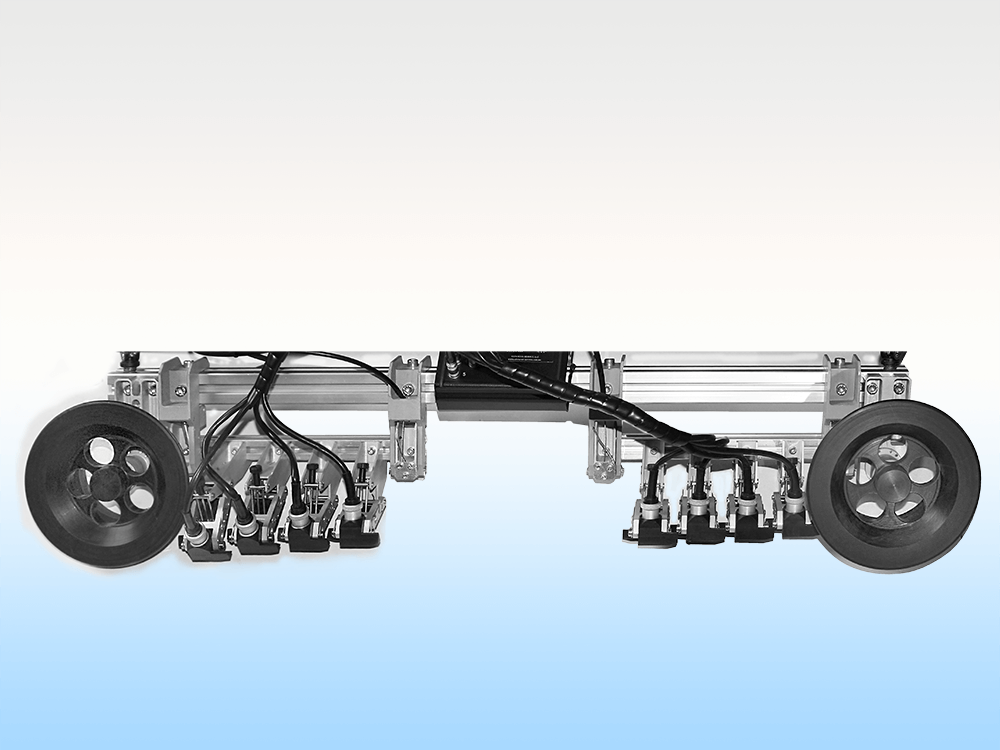

- a light aluminium frame;

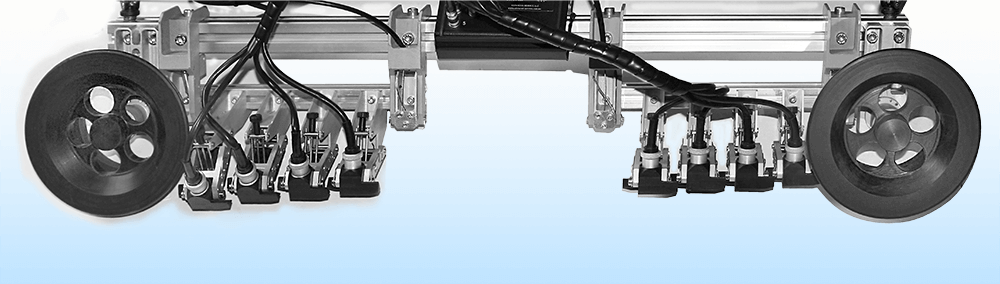

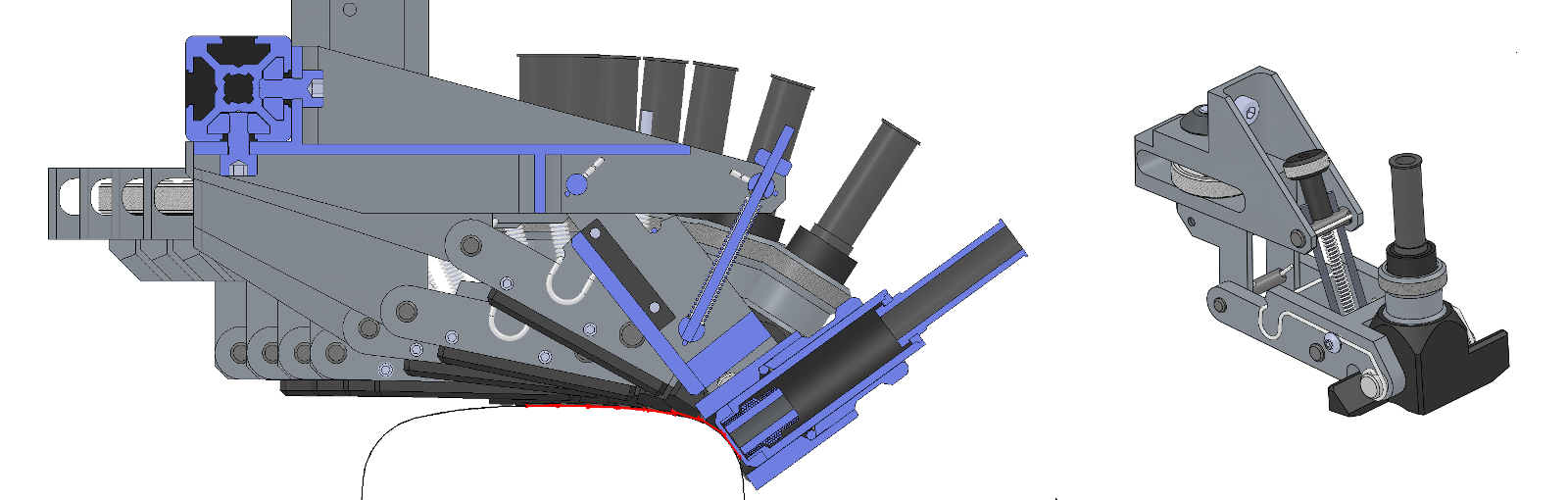

- specialized abrasion-resistant ECPs, which allow evaluating oblique cracks of up to 3 mm deep in their vertical damage;

- the use of 8 ECPs allows performing the inspection of the whole head rail surface in one run;

- individual spring-mounted fitting of each ECP;

- fast removal of the scanner during the transfer from one area to another;

- individual adjustment of the ECP position;

- operating time – no less than 8 hours;

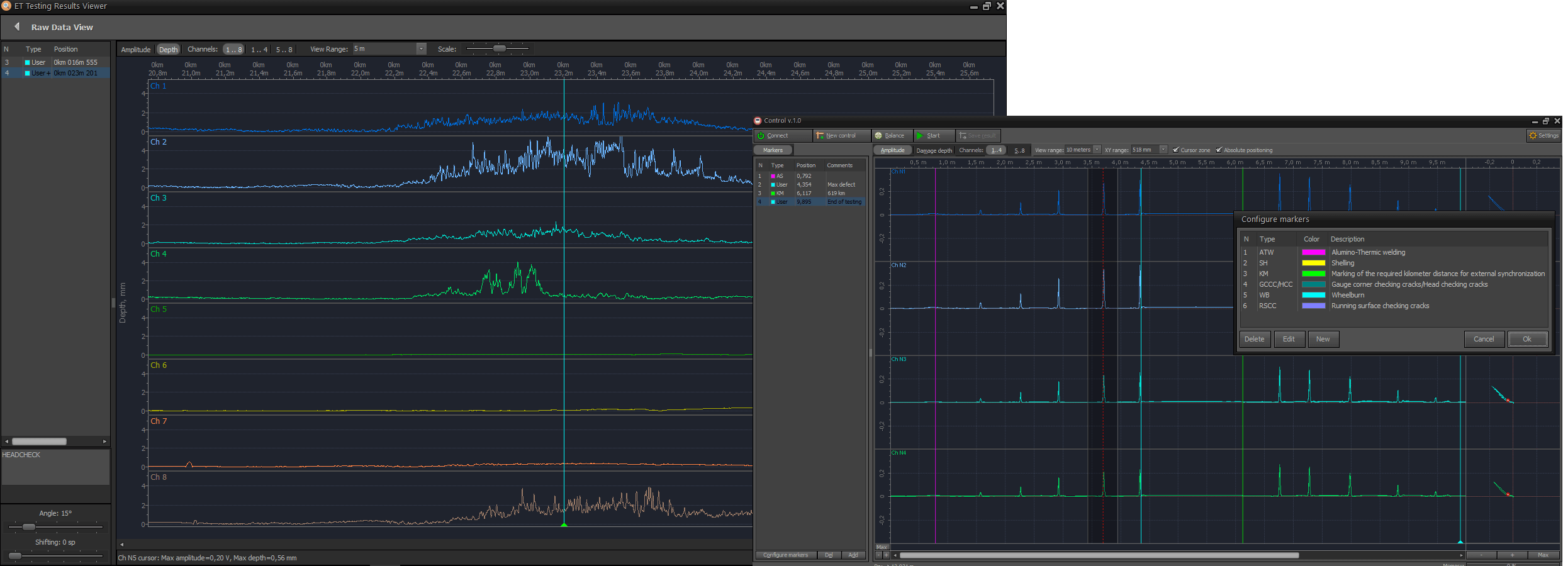

- specialized SW for setup, testing, and inspection result viewing.

SPECIFICATION

| Model | ETS2-77 |

| Flaw detector type | mechanized |

| Overall dimensions in the stowed position | 1730 mm × 900 mm × 350 mm |

| Eddy current channel | Eddycon D |

| Scanning device |

|

| ECP number | 8 |

| Tested area by one ECP | 6 mm |

| ECP protection from the abrasion and damage | Ceramic protective cover |

| Test velocity | Up to 2 m/s |

| Alarm | Visual |

| Specialized software |

|

| Operating time | 8 hours |

| Record and data storage | + PC hard disk |

| Working PC | Industrial one, IP rating 65 |