Application

The Notched Calibration Block (having plane angular reflectors) is designed for setting up the scan duration and sensitivity of flaw detectors used with the single crystal angle beam probes during the testing of the plate and tube products.

Technical data

The Notched Blocks are represented in three modifications:

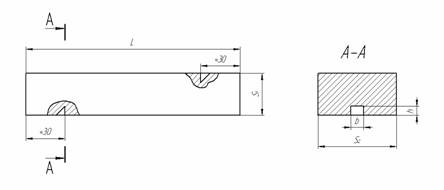

- plane – for the plane products and pipes of large diameters testing (Fig. 1 a)

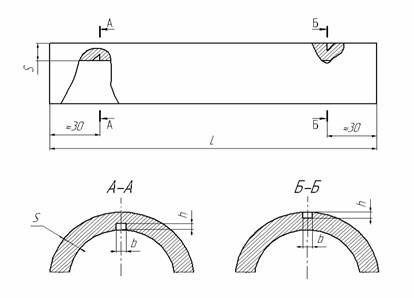

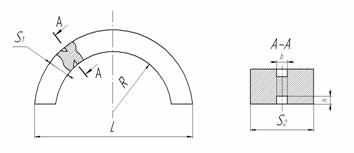

- tubular butt-end – for transverse joints and pipe bend testing (Fig.1 b)

- tubular longitudinal – for the longitudinal joints and pipe bends (Fig. 1 c)

The plane Blocks are made with one or two notches, tubular – with two notches made on the internal and external side of a pipe.

The Block is made from material of the test object. Heat treatment and quality of the Block surface shall be similar to the test object.

Geometrical dimensions of the Block are determined by the relevant regulatory and technical documents for the testing.