The ОКО-22М-EMA ultrasonic flaw detector is intended for use in high performance automated multichannel NDT Systems, mechanized NDT systems, and manual testing.

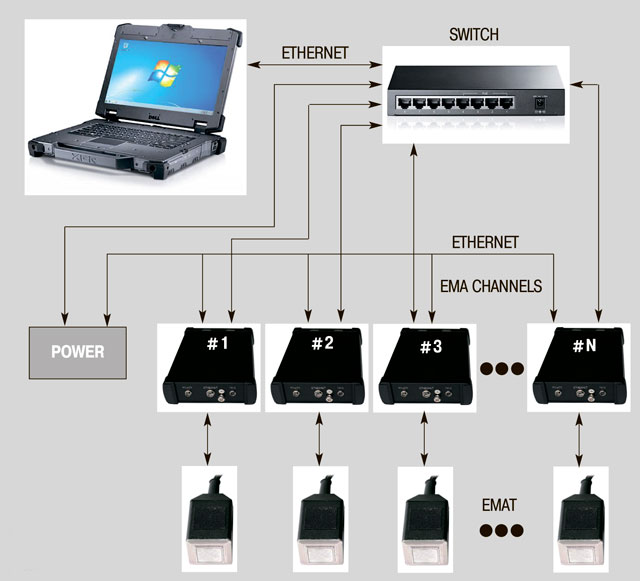

The ОКО-22М-EMA is a standalone device connected to a PC via an Ethernet port. A multichannel testing system can be created if several EMA channels are connected to the PC via the Switch unit.

The EMA technique allows performing high productivity dry ultrasonic testing in a production flow, which makes the ОКО-22М-EMA an ideal NDT solution for the field of metallurgy with its high surface temperatures.

APPLICATION OF EMA TESTING TECHNIQUE IN VARIOUS INDUSTRIES:

Production sector, test object | Regulatory Documentation | Required number of channels | Operating frequency, MHz | Special requirements |

Metallurgy, testing the flat rolled steel | EN10160, ASTM 578/A578M-96, A435A, ISO 12094 | 60 -100 | 2-3 | Test object temperature can reach to 650 oС |

Metallurgy, testing the rolled round steel bars | EN 10308, EN 10228-3, ASTM E – 2375, MS-STD – 2154 | 3-20 | 2-4 | Operating gap is 1 mm, testing velocity is up to 2 m/s |

Metallurgy, testing the slabs | - | 48-160 | 0,5; 2; 4; | Operating gap is 0.3-1 mm, testing velocity is up to 2 m/s |

Engineering, testing the pipe welded joints | API 5L, API 5 CT, EN 10246-17 | 12 | 2 - 4 | Operating gap is 1 mm, velocity is up to 1 m/s |

Engineering, testing the pipe body, thickness gauging | API 5L, API 5CT, EN 10246, ASTM E1816-96 | 56 | 2 - 4 | Operating gap is 1 mm, velocity is up to 1 m/s |

Figure 1. – EMA channel "ОКО-22M-EMA"

Figure 2. – Structural scheme for connecting the EMA channels

|  ; ; |

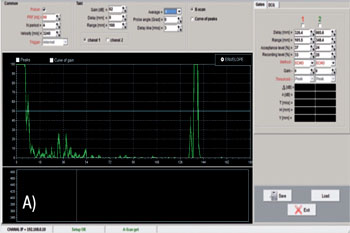

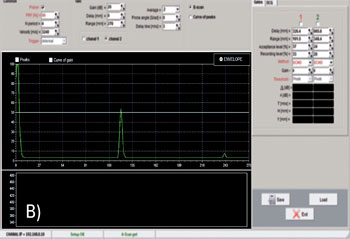

| А) | B) |

Figure 3

- А) detection of flat-bottom hole with dia. 2 mm at a depth 136 mm (EMAT - 0o - 4 MHz, testing the 140 mm bar);

- B) detection of groove with a depth 0.5 mm and length 10 mm (EMAT - 45o - 2 MHz, testing the 140 mm bar)

Catalog number | Frequency, MHz | Probe angle, o | Working surface size, mm | Connector type | Connector position |

EMAT0.5-0 | 0.5 | 0 | 20×20 | 2Lemo00/BNC | cable |

EMAT1-0 | 1.0 | 0 | 20×20 | 2Lemo00/BNC | cable |

EMAT1-90 | 1.0 | 90 | 20×20 | 2Lemo00/BNC | cable |

EMAT2-0 | 2.0 | 0 | 20×20 | 2Lemo00/BNC | cable |

EMAT4-0 | 4.0 | 0 | 20×20 | 2Lemo00/BNC | cable |

EMAT5-0 | 5.0 | 0 | 20×20 | 2Lemo00/BNC | cable |

EMAT5-45 | 5.0 | 45 | 20×20 | 2Lemo00/BNC | cable |

EMAT6-0 | 6.0 | 0 | 20×20 | 2Lemo00/BNC | cable |

| EMAT8-0 | 8.0 | 0 | 20×20 | 2Lemo00/BNC | cable |

*The working surface size and dimensions of EMA transducers can be customized. The high temperature EMAT modification is available..

Figure 4. EMA transducers

Parameter | Value | |

PULSER | ||

Initial pulse filling frequency | 0.5, 1, 2, 3, 4, 5, 6, 8 MHz; (up to 8 MHz available as an extra option) | |

Type of initial pulse | Toneburst Waveform; | |

Number of periods | 2-6; | |

Pulser amplitude | up to 2000 Vpp; | |

Pulse energy | depends on a filling frequency; | |

Pulse repetition frequency (PRF) | from 50 to 4000 Hz; | |

RECEIVER | ||

Gain adjustment | -20 to 68 dB (gain step 0.1, 0.5, 1, 2 dB); | |

Filter | 0.5, 1, 2, 3, 4, 5, 6 MHz; | |

Delay | from 0 to 1000 mm in steel (sound velocity 3230 m/s); | |

Range | from 1 tо 6000 mm in steel (sound velocity 3230 m/s); | |

Number of averages | 2 / 4 / 8 / 16 / 32; | |

Data presentation | А- Scan; B-Scan; C-Scan; | |

TCG | ||

Depth | entire gain range; | |

Number of points | not less than 20; | |

Minimum time step between TCG points | up to 1 µs; | |

Maximum slope | not less than 46 dB/µs; | |

GATES | ||

| Two independent gates per channel Amplitude and time measurements | ||

Two acceptance levels per gate | ||

A/D converter | 10 bit, 80 MHz; | |

PORTS (for communication with PC and various peripheral devices) | ||

Ethernet (for communication with PC); | ||

CONNECTORS | ||

2 lemo00 connectors for connecting the EMAT to the receiver of EMA channel; | ||

2 BNC connectors (one connector for the first pulser, second connector for the second pulser). | ||

1 lemo connector for Encoder connection; | ||

1 power connector; | ||

1 Ethernet connector for transmitting the data to PC; | ||

1 Trigger connector is used either for synchronization between EMA channels, or for EMA channel metrological verification. | ||